Why Kevlar Mesh Fabric Is the Ultimate Performance Material

Kevlar mesh fabric combines the legendary strength of aramid fibers with an open weave design that delivers best durability while staying lightweight and flexible. This high-performance material offers 5 times the strength of steel at equal weight, operates continuously from -100°F to 575°F, and meets FDA standards for direct food contact.

Key Benefits of Kevlar Mesh Fabric:

- Extreme Temperature Range: -100°F to 575°F continuous operation

- Superior Strength: 300 lbs/inch tensile strength with only 3% elongation

- Food-Safe Compliance: FDA, USDA, and NSF approved for direct contact

- Chemical & UV Resistant: Higher UV resistance than fiberglass

- Flame Resistant: Self-extinguishing properties

- Lightweight Design: Open mesh reduces weight while maintaining strength

Whether you're sourcing materials for industrial conveyors, food processing equipment, or high-performance composites, kevlar mesh fabric delivers the reliability your business demands. The PTFE (Teflon) coating option adds non-stick properties and moisture resistance, making it perfect for steam environments and easy-release applications.

From bullet-resistant vests to bakery conveyor belts, this versatile material has proven itself across industries where failure isn't an option. Let's explore how this engineering marvel can solve your toughest material challenges.

Understanding Kevlar Mesh Fabric

When DuPont™ first developed Kevlar® aramid fiber back in 1965, they probably didn't imagine it would end up protecting both police officers and your morning bagels. What started as a breakthrough material for tire reinforcement has become the backbone of countless industries where "good enough" simply isn't good enough.

At Fabric Selection Inc., we've watched kevlar mesh fabric solve problems that seemed impossible just decades ago. The magic happens when you combine aramid fiber's legendary strength with an open weave design that keeps all that performance while actually making the material lighter and more flexible.

Think of it this way: if regular Kevlar fabric is like a solid brick wall, kevlar mesh fabric is like a perfectly engineered chain-link fence - still incredibly strong, but now you can see through it, air can flow through it, and it bends when you need it to.

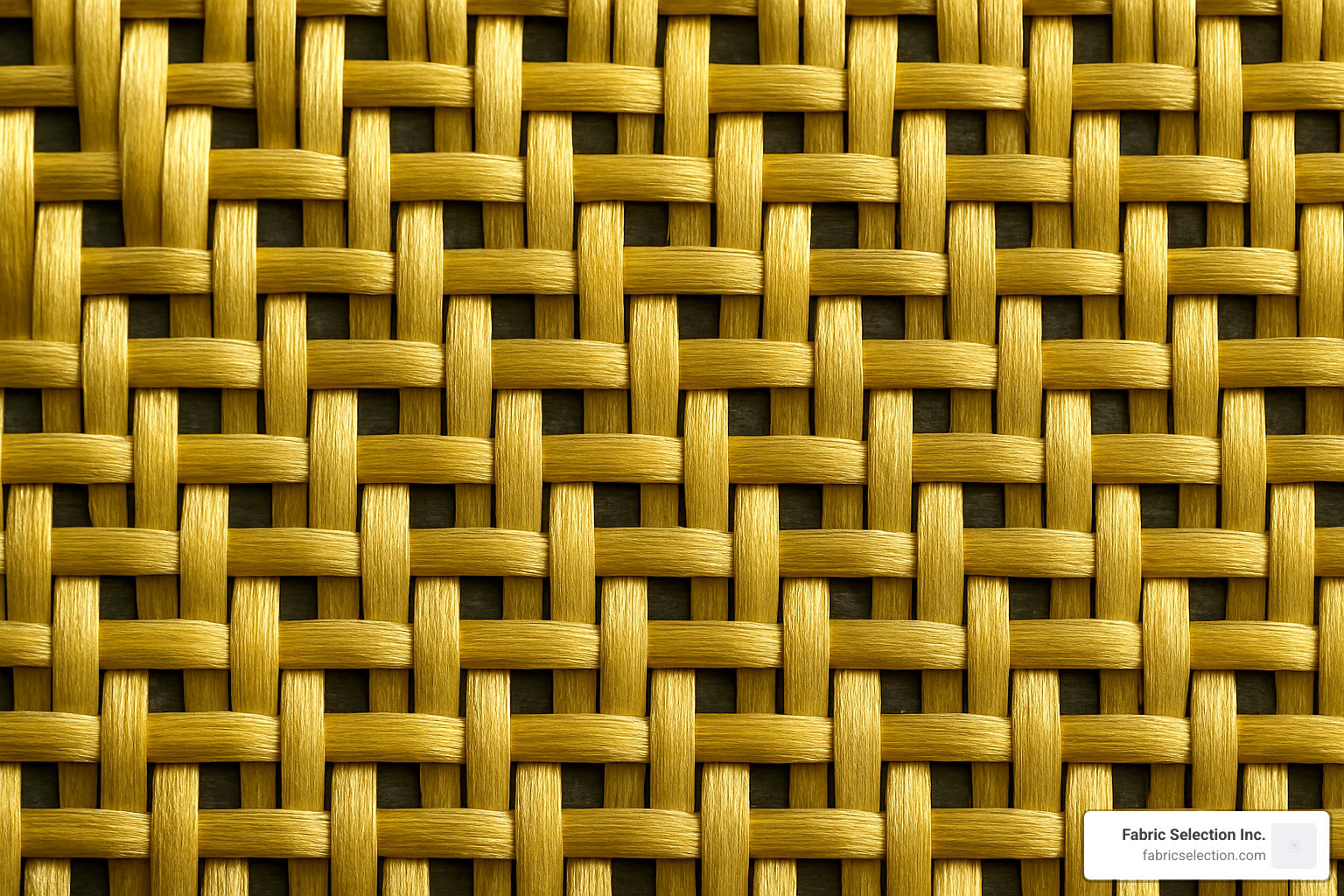

What Exactly Is Kevlar Mesh Fabric?

Kevlar mesh fabric starts with para-aramid fibers - those incredibly strong synthetic fibers with the tongue-twisting chemical name poly-para-phenylene-terephthalamide. But here's where it gets interesting: instead of weaving these fibers into a solid fabric, manufacturers create an open-area weave pattern with precisely controlled holes.

These mesh openings typically range from 1/16" to 1/4", depending on what you need the fabric to do. It's not random - every opening is carefully calculated during the weaving process to give you exactly the right balance of strength, airflow, and flexibility.

The open design isn't just about looking different. Those carefully placed holes serve some pretty impressive purposes. Weight gets reduced without losing strength, which is why aerospace engineers love this stuff. Air flows freely through the openings, making it perfect for industrial drying applications. The fabric becomes more flexible around curves and complex shapes, and in composite manufacturing, resins can penetrate better for stronger bonds.

For food processing applications, those openings make cleaning incredibly easy. No hidden corners where bacteria can hide - just smooth, accessible surfaces throughout.

How Kevlar Mesh Fabric Is Made

The journey from chemical polymer to kevlar mesh fabric is pretty fascinating. It all starts with poly-para-phenylene-terephthalamide polymer, which gets dissolved and spun into continuous filaments. These filaments are then twisted together into the high-strength yarns that give Kevlar its reputation.

The real skill comes in the weaving process. Specialized looms create that precise mesh pattern while keeping perfect tension control - too loose and you lose strength, too tight and the fabric becomes stiff and brittle. After weaving, the fabric goes through a heat-setting process that locks in the mesh geometry and improves dimensional stability.

Many kevlar mesh fabrics then get a PTFE coating through a controlled dip-coating process. This is where the material transforms from just "really strong" to "incredibly versatile." The coating adds non-stick properties and moisture resistance that make it invaluable in food processing and industrial applications.

You can find quality Kevlar fabrics and related materials that showcase the versatility of aramid fiber construction across different weave patterns and applications.

Role of PTFE Coating

Here's where kevlar mesh fabric really shows off. The PTFE (polytetrafluoroethylene) coating - you probably know it as Teflon - turns an already impressive material into something truly special.

PTFE creates a non-stick surface with friction levels second only to ice. That means materials slide right off, making it perfect for conveyor belts and food processing equipment. The coating also acts as a moisture barrier, protecting against steam and humidity that would damage other materials.

The chemical inertness of PTFE means it resists almost all industrial chemicals, acids, and alkalis. And because it meets FDA compliance standards under 21 CFR 177.1550, it's approved for direct food contact - something you definitely can't say about most high-performance fabrics.

The best part? This coating doesn't make the mesh stiff or brittle. It maintains all that flexibility and dimensional stability that makes kevlar mesh fabric so useful in the first place. You get the strength of Kevlar plus the performance benefits of PTFE, all in one material that's still flexible enough to wrap around complex shapes.

Properties & Performance You Can Count On

When you're choosing materials for critical applications, you need numbers you can trust. Kevlar mesh fabric delivers performance that honestly amazes even us at Fabric Selection Inc. - and we've been working with high-performance textiles for years.

The tensile strength hits an impressive 300 pounds per inch in the warp direction, while the tensile modulus ranges between 91-114 GPa. To put that in perspective, you're getting structural performance that rivals solid metal components at just a fraction of the weight - with a density of only 1.44 g/cm³.

What really sets kevlar mesh fabric apart is its incredibly low elongation at break - typically just 2.7% to 3.1%. This means your applications maintain their shape and dimensions under load, which is absolutely critical for precision conveyor systems and structural composites where even small changes can cause big problems.

Mechanical vs. thermal performance data comparison showing kevlar mesh fabric's superior balance of strength and temperature resistance

Temperature & Environmental Endurance

Here's where kevlar mesh fabric really shows off. This material operates continuously across an extraordinary temperature range from -100°F to 575°F (-73°C to 302°C). But what's even more impressive is its ability to maintain integrity at cryogenic temperatures as low as -320°F without becoming brittle or degrading.

We've put this material through steam environments, high-humidity conditions, and rapid thermal cycling that would destroy conventional fabrics. The dimensional stability remains rock-solid - the mesh openings don't distort, and the fabric doesn't shrink or stretch beyond specification limits.

Kevlar mesh fabric performing in high-temperature industrial oven environment

This temperature resilience makes kevlar mesh fabric invaluable for industrial drying processes with steam and moisture, cryogenic applications in aerospace and medical equipment, high-temperature filtration in chemical processing, and thermal cycling environments in automotive and electronics.

Chemical, UV & Fire Resistance

The chemical inertness of both Kevlar fibers and PTFE coating creates a material that simply shrugs off attacks from acids, alkalis, and most industrial solvents. This resistance can extend service life significantly compared to conventional fabrics - saving you money and downtime.

UV resistance actually exceeds that of fiberglass, making kevlar mesh fabric suitable for outdoor applications where other high-performance materials would gradually break down under sun exposure. The flame-resistant properties are equally impressive - the material is self-extinguishing and won't support combustion, adding an extra layer of safety to your operations.

Mechanical Muscle of Kevlar Mesh Fabric

The raw mechanical properties of kevlar mesh fabric tell a compelling story. With tensile strength of 2987-3157 MPa and exceptional cut resistance, this material provides serious protection against blade and abrasion damage - making it safer to handle during installation and maintenance.

These properties translate into real-world advantages you can count on. The high cut resistance makes handling safer for your team, while the exceptional tensile strength allows thinner, lighter designs without compromising safety margins. You get the performance you need with less material bulk.

Food-Safe & Regulatory Credentials

When it comes to food safety, kevlar mesh fabric with PTFE coating doesn't just meet standards - it exceeds them. The material is FDA compliant under 21 CFR 177.1550, USDA approved for direct food contact, and NSF certified for commercial food processing.

These certifications represent rigorous testing for chemical migration, taste transfer, and long-term safety - not just paperwork. At Fabric Selection Inc., we maintain complete documentation for all food-grade materials to support your compliance requirements, because we know how important that peace of mind is for your business.

Applications & Industries That Rely on Kevlar Mesh

The versatility of kevlar mesh fabric never ceases to amaze us here at Fabric Selection Inc. We've watched this remarkable material solve problems across industries we never expected - from bakery ovens to spacecraft components.

What makes kevlar mesh fabric so adaptable? It's the unique combination of strength, temperature resistance, and that open weave structure that breathes while it protects. Let's explore where this material really shines.

Food-Grade Conveyors & Drying Lines

Walk into any modern bakery, and you'll likely see kevlar mesh fabric hard at work. Those conveyor belts carrying bread through 500°F ovens? They're counting on the PTFE coating to prevent dough from sticking while the kevlar fibers handle the extreme heat.

Food-grade kevlar mesh conveyor belt in commercial bakery operation

Meat smoking operations have become another sweet spot for this material. The mesh structure promotes even heat circulation around products, while the fabric itself laughs off the combination of high temperatures and steam that would destroy conventional materials.

We've had customers tell us their production lines run smoother because the easy-release surface means less downtime for cleaning. When you're processing food, every minute of downtime costs money - and kevlar mesh fabric keeps those lines moving.

Composite Reinforcements & Hybrids

Here's where things get really interesting. kevlar mesh fabric doesn't just reinforce composites - it makes them smarter. While carbon fiber gives you stiffness, kevlar gives you the ability to survive impacts that would shatter pure carbon composites.

Carbon-kevlar hybrid fabrics have revolutionized everything from kayak hulls to drone frames. A kayak needs to flex when it hits rocks, not crack. A drone frame needs to survive those inevitable crashes while staying light enough to fly efficiently.

The mesh structure works beautifully in composite applications because resin flows easily through those precise openings, creating strong bonds without air pockets. Plus, those open areas reduce the final weight - critical when every gram matters in aerospace or automotive panels.

Learn more about how unique materials drive innovation in modern manufacturing.

Safety, Defense & Extreme Sports

Cut-proof gloves made with kevlar mesh fabric solve a problem that solid kevlar can't - they actually breathe. Traditional cut-resistant gloves leave workers' hands sweaty and uncomfortable, but the mesh structure allows airflow while maintaining that legendary cut protection.

Flame-resistant aprons for welders and metalworkers benefit from the same principle. You need protection from sparks and heat, but you also need to stay cool enough to work effectively. The mesh design delivers both.

Motorcycle apparel represents another growing application. Riders want protection from road rash, but they also want comfort during long rides. kevlar mesh fabric panels in riding gear provide abrasion resistance with ventilation - especially valuable in warmer climates where solid protective panels become unbearable.

The beauty of these applications lies in solving the classic trade-off between protection and comfort. With kevlar mesh fabric, you don't have to choose.

Kevlar vs. Fiberglass vs. Carbon Fiber

When you're choosing high-performance fabrics, understanding the differences between kevlar mesh fabric, fiberglass, and carbon fiber can save you time, money, and headaches down the road. Each material has its sweet spot, and picking the wrong one can lead to costly failures or over-engineered solutions.

Kevlar mesh fabric sits in the middle ground between budget-friendly fiberglass and premium carbon fiber - but that doesn't mean it's a compromise. In many applications, it's actually the superior choice.

Let's look at how these materials stack up:

| Property | Kevlar Mesh | Fiberglass | Carbon Fiber |

|---|---|---|---|

| Strength-to-Weight | Excellent | Good | Excellent |

| Impact Resistance | Superior | Poor | Fair |

| Temperature Range | -100°F to 575°F | -50°F to 300°F | -100°F to 400°F |

| Chemical Resistance | Excellent | Good | Fair |

| Cost | Moderate | Low | High |

| Food Safety | FDA Approved | Limited | No |

| UV Resistance | Superior | Poor | Excellent |

Impact resistance is where kevlar mesh fabric truly shines. While carbon fiber might crack under sudden impact, kevlar absorbs and distributes the energy. This makes it perfect for applications where things might get bumped, dropped, or subjected to vibration.

The temperature range advantage is significant too. Fiberglass starts losing strength around 300°F, while kevlar mesh keeps performing up to 575°F. That's the difference between a material that works in your steam environment and one that fails.

Cost considerations often drive material selection, and here's where kevlar mesh offers real value. It delivers performance that's often 80% of what you'd get from carbon fiber at roughly 40% of the cost. For most applications, that's a winning combination.

When to Pick Kevlar Mesh Fabric Over Others

Choose kevlar mesh fabric when your application demands superior abrasion resistance for high-wear environments. We've seen fiberglass fabrics wear through in months where kevlar mesh lasts years in the same conveyor application.

Food contact approval is another clear win for kevlar mesh. Neither fiberglass nor carbon fiber can match the FDA, USDA, and NSF certifications that come standard with PTFE-coated kevlar mesh fabric. If you're processing food, this isn't negotiable.

High-temperature flexibility matters when your material needs to bend and flex in heat. Carbon fiber becomes brittle, and fiberglass loses strength, but kevlar mesh maintains its flexibility even at liftd temperatures.

When you need impact tolerance over ultimate stiffness, kevlar mesh is your best bet. Racing applications, protective equipment, and portable structures all benefit from kevlar's ability to absorb energy rather than transfer it.

Finally, kevlar mesh fabric offers budget-conscious performance that bridges the gap between basic fiberglass and premium carbon fiber. You get professional-grade performance without the premium price tag.

The decision often comes down to matching your specific performance requirements with cost considerations. At Fabric Selection Inc., we help our customers analyze these trade-offs to select the optimal material for each application. Sometimes the most expensive option isn't the best solution - it's about finding the right fit for your needs.

Selecting, Handling & Caring for Your Mesh

Choosing the right kevlar mesh fabric feels a bit like picking the perfect tool for a job - get it right, and everything works beautifully. Get it wrong, and you'll be kicking yourself later.

The mesh opening size makes a huge difference in performance. Fine 1/16" openings work perfectly for precise filtration applications, while larger 1/4" openings maximize airflow for drying operations. Think about what needs to pass through your mesh - steam, air, small particles, or just heat.

Fabric weight is your next big decision. Lightweight 170 g/m² options handle delicate applications where flexibility matters most. Heavy-duty 465 g/m² fabrics tackle the tough jobs where durability trumps everything else. Most of our customers at Fabric Selection Inc. find their sweet spot somewhere in the middle.

Cost always enters the conversation, and honestly, it should. Base fabric weight affects pricing more than most people expect. PTFE coating adds value but increases cost - only specify it if you truly need those non-stick properties. Custom specifications cost more than standard products, but sometimes they're worth every penny for the perfect fit.

Our Los Angeles location means we can get standard configurations to you quickly across the western United States. For custom work, we'll walk you through the timeline upfront so there are no surprises. We're committed to delivering the quality materials you deserve.

Practical Buying Checklist for Kevlar Mesh Fabric

Before you place that order, take a moment to think through your real-world needs. Temperature range matters more than most people realize - that 575°F upper limit sounds impressive until you need 600°F. Chemical exposure can be tricky too. Just because kevlar mesh fabric resists most chemicals doesn't mean it resists the specific ones in your process.

Regulatory approvals like FDA, USDA, or NSF certification aren't just nice-to-have features if you're in food processing. They're absolutely essential, and getting them sorted out after the fact is a headache you don't want.

Mesh opening size affects everything from material flow to cleaning ease. PTFE coating transforms the fabric's behavior, but it's not always necessary. Quantity requirements and supplier minimums can catch you off guard if you're not prepared. Delivery timeline planning prevents those last-minute panic calls.

We've helped hundreds of customers work through these decisions, and we're happy to share what we've learned along the way.

Maintenance & Longevity Tips

Taking care of kevlar mesh fabric isn't complicated, but a few simple steps make a world of difference in service life. UV light is the enemy here - store your fabric away from windows and bright lights. We recommend keeping rolls in tubes or covered areas.

When cutting time comes, grab serrated scissors instead of regular ones. The difference in cut quality is remarkable, and you'll avoid that annoying fraying that makes installation harder. Edge sealing with tape or fray-check before cutting saves time and frustration later.

Regular inspection catches problems before they become failures. Look for mesh distortion where the openings have stretched out of shape. Check for coating wear in high-friction areas. Watch for individual fiber damage that could spread.

Cleaning needs to match your application requirements. Food-grade installations require specific procedures to maintain compliance. Industrial applications might need different approaches. We provide cleaning guidelines with every order because proper maintenance is half the battle in getting long service life.

Proper storage of kevlar mesh fabric rolls in protective tubes to prevent UV damage

The best part about kevlar mesh fabric is how forgiving it can be when you treat it right. Follow these basics, and you'll be amazed how long it keeps performing.

Frequently Asked Questions about Kevlar Mesh Fabric

We get these questions about kevlar mesh fabric almost daily at Fabric Selection Inc. After years of working with customers across industries, we've learned that the same concerns come up repeatedly - and for good reason. These are the make-or-break details that determine whether this material will work for your specific application.

Is Kevlar Mesh Fabric Safe for Direct Food Contact?

Absolutely, and this is one of the biggest advantages of kevlar mesh fabric with PTFE coating. The material meets the strictest food safety standards including FDA compliance under 21 CFR 177.1550, USDA approval, and NSF certification for direct food contact applications.

This isn't just a rubber stamp approval either. These certifications require extensive testing for chemical migration, taste transfer, and long-term safety under real-world conditions. We maintain complete documentation for all our food-grade materials, so you'll have everything needed for your compliance audits.

The combination of Kevlar fibers and PTFE coating creates a surface that won't react with foods, won't transfer flavors, and can handle the cleaning chemicals required in commercial food processing. That's why bakeries trust it for their oven conveyors and meat processors use it for smoking racks.

How Does PTFE Affect Fabric Breathability?

The PTFE coating does reduce breathability compared to bare kevlar mesh fabric, but you're not losing the airflow benefits entirely. The open mesh structure still allows significant air movement - it's just somewhat restricted by the coating thickness.

Think of it like a screen door with a thin film on it. The openings are still there, but the airflow is reduced. The actual impact depends on two key factors: coating thickness and mesh opening size. Heavier coatings reduce permeability more than light coatings, and larger mesh openings maintain better airflow than smaller ones.

For applications where maximum airflow is critical, we can recommend specific coating specifications that balance your non-stick requirements with breathability needs. It's all about finding the sweet spot for your particular application.

Can I Use Kevlar Mesh Fabric Outdoors Long-Term?

Kevlar mesh fabric handles outdoor conditions much better than fiberglass alternatives, but "long-term" outdoor exposure does present some challenges. The UV resistance is genuinely superior - you'll see gradual discoloration and some strength reduction over time rather than the rapid degradation that hits other materials.

The reality is that prolonged direct sunlight will eventually affect any textile material. With kevlar mesh fabric, you're looking at a gradual process rather than sudden failure. The fabric typically shows color changes before any significant strength loss occurs, giving you plenty of warning.

For critical outdoor applications, we often recommend UV-stabilized versions when available, or suggest protective covers during periods of non-use. The extra protection can extend service life significantly while maintaining the performance you need when the application is active.

The key is matching your expectations to the actual exposure conditions. Occasional outdoor use? No problem at all. Permanent installation in direct desert sun? You'll want to plan for periodic replacement or additional protection measures.

Conclusion

After diving deep into kevlar mesh fabric, it's clear why this material has become the go-to choice for applications where ordinary fabrics just won't cut it. The combination of aramid fiber strength, carefully engineered mesh openings, and optional PTFE coating creates something truly special - a fabric that laughs in the face of extreme temperatures while maintaining the flexibility and breathability you actually need.

Think about it: where else can you find a material that handles everything from -100°F to 575°F, meets strict FDA food safety standards, and still weighs less than your morning coffee? Whether you're designing bakery conveyors that need to release sticky dough effortlessly or building composite kayak hulls that can survive a rocky shore encounter, kevlar mesh fabric delivers the kind of reliability that lets you sleep well at night.

What makes this material truly versatile is how it solves multiple problems at once. The strength and cut resistance keep your workers safe. The temperature tolerance handles whatever your process throws at it. The food-grade certifications satisfy the most demanding regulatory requirements. And the open mesh design keeps weight down while improving airflow - solving trade-offs that have frustrated engineers for decades.

At Fabric Selection Inc., we've seen how the right material choice transforms entire operations. Our customers tell us stories about reduced downtime, improved product quality, and operations that simply run smoother when they switch to kevlar mesh fabric. That's the kind of impact we love to hear about.

Based right here in Los Angeles, we understand that your material needs don't wait for convenient business hours. Our competitive pricing and fast shipping mean you get the high-performance fabrics you need without the premium pricing or lengthy delays. We're not just selling fabric - we're supporting your success with materials that perform when it matters most.

Ready to see what kevlar mesh fabric can do for your specific application? Our technical team knows these materials inside and out, and we'd love to help you find the perfect mesh opening size, weight, and coating combination for your needs. Sometimes the best solutions are simpler than you think.

Find more innovations in fabric technology and see how advanced materials continue to push the boundaries of what's possible in manufacturing and design.